Event-driven Incoming Goods Inspection

iQ-BASIS offers various modules with different tasks and quality strategies for the quality complex of purchased parts. The iQ-EWEP component was developed as an extension to the classic iQ-WEP goods receipt inspection, which is essentially based on statistical methods, and offers practical additions and simplifications for common situations between suppliers and customers.

Workflow

iQ-EWEP is used for qualified suppliers, large series, and parts from controlled processes. For frequently recurring inspections, events and inspection strategies can be defined that result in a sensible and economical inspection effort. For parts with higher defect rates, new parts, and new suppliers, iQ-WEP sometimes requires more time-consuming monitoring for a limited period.

Event-driven goods receipt inspection is most effective when used in conjunction with the iQ-QMS quality messaging system and the iQ-PROJEKTE module for action management.

Important Features at a Glance

Inspection Planning

The procedure and scope of the respective incoming goods inspection are essentially determined by the inspection plan. The iQ-PLAN module description describes this in detail. A few points are mentioned here.

- Detailed inspection plan if a single part is to be inspected only occasionally, but thoroughly

- A Global inspection plan for any number of parts; contains only a few general characteristics (possibly only inspection according to drawings or general inspection, etc.)

- The global inspection plan is supplemented by the inspector's knowledge database (see iQ-WEP)

- can be created entirely by adding unplanned features during inspection

- By providing a detailed description of the error

- The inspection plan type (global/detailed) can be selected specifically depending on the current situation.

- Sample size can be assigned for specific characteristics or be the same for all characteristics (inspection: checks 2 parts)

- All control options for inspection described in iQ-WEP also apply in iQ EWEP.

Ship to Stock contracts (STS)

- Only n deliveries are checked at the beginning of a specified period (e.g., once a year).

- The last inspection can be determined from the history by activating STS.

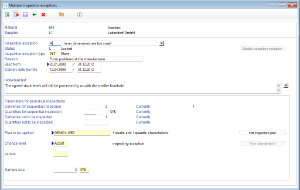

Periodic Inspection

The specifications always apply to one part number from one supplier.

With event-driven checking, it is assumed that a large number of deliveries will be accepted without being checked. There is a control for this that relates to deliveries:

- Specification of the number of consecutive deliveries or quantities to be checked.

- Specification of the number of consecutive deliveries or quantities not to be checked.

- If quantity and deliveries are specified at the same time, the more critical requirement applies.

- Info on the current situation (5 consecutive deliveries to be checked, 3 of which have already been checked).

- Selection of the inspection plan to be used (detailed/global).

- Specification of the sample size (number of parts to be inspected, e.g., n=2).

The following inspection tasks for more events are structured similarly:

- Batch change

- Recording of the delivery batch with the goods receipt or separately from it

- Determination of batch characteristics; only the specific characteristics of the batch are inspected

- New drawing change

- Recording the change index in goods receipt (e.g., VDA document) or specifying new change indexes after change notification

- Determination of the characteristics to be tested that are affected by the change

Time-limited inspection

- Specification of amount of inspections

- Until a certain point in time

- From a certain point in time

Construction deviation/inspection exception

- Recording of construction deviations

- Status

- Type (interne specification, supplier request)

- Reason

- Period of validity

- Storing an inspection plan change status for a construction deviation

- Control of the inspection plan change status over validity period

- Determination of the characteristics to be tested that are affected by the construction deviation

Event-driven Mechanism

Various pieces of information can trigger an inspection for the next delivery of a part from a supplier:

- Supplier has changed the process; in this case, an initial sample inspection can be enforced before the normal inspection.

- New change index from the design department.

- Quality assurance has identified quality defects at the supplier through a supplier audit.

- Production or assembly have blocked defective purchased parts.

- Customer service has noticed a high return rate for purchased parts

- Customer complains about parts due to defects in purchased parts, etc.

In various modules, an event can or must be created for a supplier part. The following specifications apply for inspecting during active event control:

- Number of consecutive deliveries to be inspected and/or

- Number of quantities to be checked in sequence

- Inspection plan to be used, e.g., detailed inspection plan

- Sample size

Inspection Order Mechanism

A series of conditions is checked with each delivery:

- Is periodic inspection activated?

- Has an event occurred?

- Is there still an initial sample inspection order open?

- Is there still a periodically scheduled inspection order open?

Supply Chain

As long as a decision on an existing older goods receipt is still pending, every new inspection order is placed in a queue.

If the previous usage decision is OK, the inspection waiver can be permitted.

Initial sample inspection orders and re-inspection orders are fully integrated into this system.

Inspection

The inspection is performed in the same way as for a check request for the iQ-WEP component. The same applies to the usage decision and the entry in the history.

Re-inspection Orders

The re-inspection order is necessary, e.g. if problems with a purchased part have been identified in production and stock levels need to be checked as a result.

The following applies to the re-inspection order:

- Manuel creation

- Free choice of inspection plan and specification of sample size (e.g., 100% inspection)

- Inspection as in iQ-WEP

- Usage decision as with iQ-WEP, but no feedback to EPR

- Entry in history with verification flag

Interface with Complaint Management

The iQ-QMS module is a powerful component for recording, analyzing, and resolving quality issues, including complaints about purchased parts that are not detected during incoming goods inspection, but only during further processing or when analyzing a customer complaint. In iQ-QMS, the defect can be analyzed and described in detail in the quality notification. An event can be set up for the quality notification.

The defect analysis from the quality notification is displayed to the inspector at the time of the next mandatory incoming goods inspection.

Interface to other Modules

- iQ-PLAN for planning defaults

- iQ-QMS for creating and processing supplier complaints

- iQ-LIEFBEW for calculating supplier parameters