Inspection Orders

The module iQ-PAUF is a homogeneous system for all types of inspection orders. The functions described can be applied to all types of orders as far as it is reasonable. Since inspections take place in different situations, but inspections are mostly uniform, the system is easily understood and accepted. This applies for the initial inspection as well as for the calibration of gauges.

Types of Orders

- initial inspection

- receiving inspection

- event driven receiving inspection

- revision inspection

- product inspection

- mounting inspection

- laboratory inspection

- gauge calibration

- plant maintenance inspection

Following global functions will be described briefly

- generating inspection orders

- contents can be changed and added

- control and supervision of inspection orders

- realisation of the inspection tasks

- usage decisions

- analyses

- reorganisation and archiving

- cancel inspection orders

The Functions in detail

Generating Inspection Orders

- each type of inspection order requires different contents and preconditions for generation

- the generation can take place in exchange with the user or

- inspection orders can be generated automatically by initiation of the production planning system

- an inspection plan is used to generate the order. Different types of plans can be selected

- detail inspection plan

- variant plan

- family plan

- individual plan (for special supplier)

- global plan

- system inspection plan

- treatment of temporary engineering changes

- acquisition of all important additional information

- article, supplier, quantity of parts

- planned/real date of delivery

- planned/real quantity of parts to be delivered

- Charge, serial No., manufacturer initial sample, No. of parts delivered and No. of parts to be inspected

- considerable information about shop order

Editing of Inspection Orders

- change of the most frequent entries: dates, quantities, sample sizes, No. of samples etc.

- new assignment of inspection places

- change characters

- addition of new and unplanned characters

Inspection Order Controlling

- controlling of scheduled dates

- controlling of resources

- interface to MS-Project

Inspections

Each type of inspection order may contain different functions (as listed below)

Common functions are

- overviews of inspection operations

- overviews of characters

- texts, several drawings and pictures for each order or character

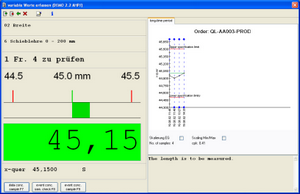

- support of gauges connected online

- entering of additional information

- about inspection operation

- about a sample

- about a character i. e.

- charge, serial No., manufacturer

- machine, tool, cavities

- shop order information

- entering id’s of all gauges used for all characters of an inspection operation

- individual texts

- events and actions

- description of defects (quality characters) failure modes, locations, causes

- initial values (quantity characters)

Special Functions

- initial inspection order

- enter initial value of supplier and customer

- enter defect attributes of quality characters for supplier and customer

- gauge inspection order

- enter initial value and referential value

- enter gauge id and measuring array for calculating the correct value

- display of corrected value (in percent)

- display uncertainty

Use Decision

- comprehensive possibilities to analyse the history

- display and evaluation of results for each character

- information added by the inspector

- partial decisions about different quantities of delivery etc.

- reason of complaint

- kind of disposition

- disposition information in connection with the production planning system

- additional remarks about the decision

- use of standard texts about inspection reports

- inspection reports in different languages

- return decision to production planning system

- entry of decision into history

- comprehensive decision about single parts, lots, samples, periods etc. for production planning.

Evaluations

- all standard evaluations

- complete integration of qs-STAT (Q-DAS) including all statistical evaluations