Receiving Inspection

iQ-BASIS offers various modules with different tasks and quality strategies for the quality complex of purchased parts. The iQ-WEP component fulfills the classic requirements for incoming goods inspection, which are essentially based on statistical methods. The iQ-EWEP component (event-driven incoming goods inspection) was developed for ppm deliveries and zero-defect strategies, among other things.

Workflow

Like all modules with an inspection function, iQ-WEP is based on an inspection plan previously created in iQ-PLAN. The particularly economical solution of automatic generation from a CAD drawing is recommended here (see also iQ-CAD-Interface).

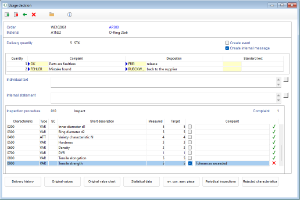

In order to perform the actual inspection, an inspection order must first be created. This process can be carried out manually or automatically by triggering it from the ERP system.

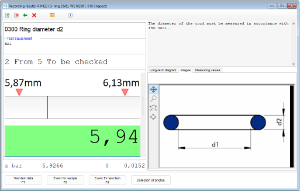

Different views allow the inspector to make optimal use of the inspection environment for the upcoming task. The ability to connect measuring devices or machines enables us to achieve maximum cost-effectiveness. The decision on use is the final step before the delivered goods are released.

Defective goods can lead directly to a supplier complaint and be processed further there.

In the supplier evaluation iQ-LIEFBEW, the results are presented coherently in the history of a supplier's parts, together with entries from sampling and supplier complaints.

Important Features at a Glance

Inspection planning in the course of the purchased part inspection

The procedure and scope of the respective incoming goods inspection are essentially determined by the inspection planning. The module description iQ-PLAN describes this in detail. A few points are mentioned here.

- Random sampling procedure with AQL specification; additionally, the starting level as well as the highest and reduced level

- Skip control per procedure and characteristic

Generating Inspection Orders

The incoming goods inspection order can be generated manually or in the background via an interface to the ERP system. In either case, the following data is required:

- Supplier and his delivering plant

- Material no.

- Order no., delivery note, etc.

- Amount of delivered an ordered quantity for the calculation of the quantity reliability

- Information about the delivery and order date for calculating delivery reliability

- Batch specifications

- Information about priority and target inspection date

- Note

The standard options are generally described for all inspection-oriented modules in the iQ-PAUF product sheet.

Inspection preparation

- Adding unplanned characteristics to the inspection order during the inspection. This option allows experienced inspectors to gradually establish standardization without having to carry out extensive inspection planning.

- Specific authorization to change the inspection requirement up to the specification limit

Inspection process

- Recording of variable and attributive quality data in various display formats, depending on requirements, either part-related or characteristic-related

- Support for the inspector through visual representation of limit patterns for error detection in direct comparison

- Additional information about the test specimen, such as serial number, batch details, etc.

- Recording of special anomalies in events

Inspector's knowledge base

- During the inspection, the inspector has the opportunity to create or expand their own error catalog.

- The error reference only applies to the parts reference, i.e. only to this part from this supplier.

- Control of the automatic usage decision when no errors have been detected.

- Entry of the usage decision with precise verification details in the history of the parts supplier purchase

- Partial dispositions

- Return information of the usage decision to the ERP system

- Printing the inspection report as a standard form

- Printing with shared distribution list for individuals, departments, and business partners

Complaints

- Jump directly from the usage decision

- Handover of the error pattern

- Further processing of the complaint by colleagues in iQ-QMS

History of the supplier evaluation

- Calculation of the quantity reliability and delivery reliability from the goods receipt notification and the delivery quality after the completeness check

- Calculation of quality indicators for initial samples and series parts after testing has been carried out

- Various control mechanisms for the introduction of the iQ-BASIS package "purchase", e.g., that all parts do not have to be re-sampled for the first few months

- Delay of all incoming goods inspections and approvals until the final initial sample decision

- Clear overview of all deliveries for a part from a supplier in the history

Evaluations

- For variable characteristics: Value progression as an original value chart

- For attributive characteristics: Pareto analysis and p-chart

- Cost overview: target/actual for inspection expenses

- Random sample and original value overviews

Output

- Goods accompanying and inspection lot removal slip

- Inspection instructions - optionally with pictures

- Internal and supplier test reports and measurement reports

Interfaces to other Modules

- iQ-PLAN for planning defaults

- iQ-EWEP for expanded options for controlling the inspection obligations

- iQ-CAD-Interface for automatically building an inspection plan from a CAD drawing

- iT-IMAGE for storing images assigned to a characteristic of an inspected part

- iT-IMPORTFILTER for reading measurements from a measuring machine

- iQ-EMP for initial sampling inspections

- iQ-QMS for creating and processing supplier complaint

- iQ-LIEFBEW in the context of the iQ-BASIS package "Purchasing" for calculating performance indicators for suppliers