Supplier Evaluation

Products are becoming increasingly powerful and ambitious. Nowadays, hardly any company manufactures all of a product's components itself. Close cooperation involves suppliers in all phases of the product, from design to disposal. Supplier evaluation (iQ-LIEFBEW) helps to assess a supplier in terms of quality indicators such as quality, logistics, price, and service/systems, as well as different reports.

Workflow

The supplier-related modules provide condensed data on delivery quality to the iQ-LIEFBEW module. The data is then evaluated and classified using a defined procedure. The evaluation is carried out in a variety of ways, using standard overviews and statistics wherever possible. These cover the general requirements, but iQ-INFO also provides users with a system that allows them to answer their own questions in overviews, graphics, or even forms.

Important Features at a Glance

Different Perspectives

Delivery history of a supplier

- Items delivered by a supplier; individually and in summary for a period of time

- Delivery reliability for items from a supplier

- All deliveries with summary of results

Delivery history of an item

- All suppliers of an item with a quality rating

- Monthly evaluation

- Hit list of suppliers

- Delivery reliability of suppliers in comparison

Quality Assessment from Inspections

- Reason for the inspection, e.g., initial delivery, new change index, etc.

- Summary of measurement results for each characteristic

- Scope of the inspection

- Reference to the inspection order

- Usage decision for dimensional accuracy, material, and function; overall decision on use

Incoming goods inspection, event-driven IGI, re-examination

- Inspection order, inspection plan

- Evaluation for each characteristic as well as summary of measurement results

- Events of the inspector

Display of Quality Indicators

Summary evaluation of a supplier (weighting and evaluation). The quality data comes from the usage decisions of the inspections, supplier complaints (8D reports), ppm evaluations, and supplier audits of the iQ-BASIS modules, as well as from manually added assessments. You can create your own evaluation catalogs. The following are available as standard:

- Deadline reliability

- Quantity reliability

- Delivery quality

Quality

- Initial sampling

- Series parts

- Complaints

- Customer complaints

Service

- Goodwill

- Due date 8D report

- Repairs etc.

Price

- Price comparison

- Price stability

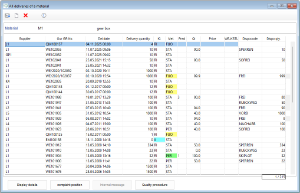

Overviews of all inspection orders for the parts/supplier's combination, complete delivery history

- Initial sample

- Incoming goods

- Skip lots - Assumptions without inspection

- Review

- Event-driven checks (error analyses from quality notifications)

- Reports of all/individual parts of a delivery

- Reports of all/one supplier for a part

Display of Q key figures (VDA, Bosch) and ppm evaluation (list, graph)

- Monthly statistics QKZ, ppm

- Target specifications from ppm contracts

- Reference to the inspection order

- Multiple different material dispositions per usage decision

- Specification of quantity, disposition (free, return delivery, etc.) and complaint (OK, no dimensional accuracy, etc.)

- Evaluations by the dispatcher in the form of standard texts

Various statistical analyses

- Monthly quality indicators for suppliers per item

- Monthly quality indicators for supplier items

- Monthly statistics for ppm evaluations

- Pareto analysis of error types

- Complete evaluations of history and disposition

- List of the worst parts

- Evaluations for Bosch assessment procedures

- Throughput times of inspection lots

- Overviews for articles with ppm specifications

- Incoming goods overview with free choice statistical reports (incl. export) with various selection criteria

- Monthly statistics on complaints/supplier comparison

- Custom reporting; the customer can use the e.g. Crystal reporting system to create statistics, graphs, forms and reports

Interfaces to other Modules