PPAP / PPF

The relationship between customer and supplier is subject to constantly increasing quality and efficiency requirements, especially in the automotive sector. In order to keep up with this development, VDA and QS9000/ISO 16949 have defined the new processes "Production Process & Production Release Procedure (PPF)" and "Production Part Approval Process (PPAP)" as enhancements of the classical Initial Sample Inspection. These new processes clearly describe how the supplier has to be able to consistently prove the quality of its processes and products. The module iQ-PPAP/PPF meets the requirements of both procedures and efficiently supports any involved persons in fulfilling their duties against their customers as well as in tracing the PPAP's/PPF's to be presented by the suppliers.

Workflow

iQ-PPAP/PPF supports the user in planning, execution and documentation of all actions linked to a PPAP/PPF. Demands are available as planning elements that have already been set up to define who has to carry out a PPAP/PPF according to which method and for which customer. The latter is done within the central part of iQ-PPAP/PPF, the test report. This is where general data about the method, the supplier and the customer, the relevant template, test reports, actions, documents etc. are maintained and administrated - supported by the software wherever it makes sense. After completion of the PPAP/PPF the supplier has a comprehensive compilation of all certificates and documents as required by the chosen method. With this compilation the standard-conforming quality of all processes and products can be proven to the customer. The most important methods are delivered as demand catalogues with the submission levels defined for them. The can be edited by the user as new report types.

iQ-PPAP/PPF supports the user in planning, execution and documentation of all actions linked to a PPAP/PPF. Demands are available as planning elements that have already been set up to define who has to carry out a PPAP/PPF according to which method and for which customer. The latter is done within the central part of iQ-PPAP/PPF, the test report. This is where general data about the method, the supplier and the customer, the relevant template, test reports, actions, documents etc. are maintained and administrated - supported by the software wherever it makes sense. After completion of the PPAP/PPF the supplier has a comprehensive compilation of all certificates and documents as required by the chosen method. With this compilation the standard-conforming quality of all processes and products can be proven to the customer. The most important methods are delivered as demand catalogues with the submission levels defined for them. The can be edited by the user as new report types.

When working with iQ-PPAP/PPF, the user benefits from a handy overview of the actually important methods, demands and reports. The user has direct access to every element and can carry out the necessary editing.

Overview of important functions

General use of the software

- Quick overview of the methods, demands and reports relevant to the user, possibility to directly access every element

- One-click-access to the most recently used PPAP/PPF

- Demand-oriented planning of test reports

- Selective search for reports, demands and methods

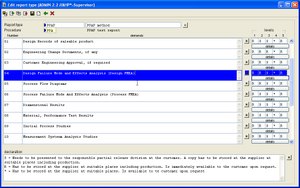

Report types/methods

Preinstalled standard methods like e.g. PPAP and PPF

Preinstalled standard methods like e.g. PPAP and PPF

- Adding of new report types from scratch or by copying and editing of available methods/report types

- Maintaining a list of reasons for a report type

- Adding, editing and deleting of demands including the corresponding submission levels

- Detailed specification of demands with an extended text and a short description

Reports

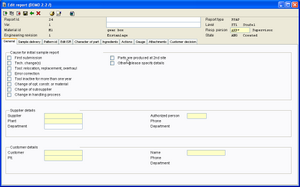

Setup

- Catalogue-supported choice of material the report is based on, the report type, the demanded submission level and the person responsible

- Automatic generation of the template (that applies to the demands catalogue relevant for the report) from the chosen report type and the submission level

- Tracking of a version number for the report

- When using demands transfer of all data defined in the respective demand

Administration data

Choice of one or several reasons for the PPAP/PPF

Choice of one or several reasons for the PPAP/PPF

- Catalogue-based declaration of the most important information about supplier and customer

- Detailed information about a possible sample delivery that describe the sample as well as the article on the customers side

- Subsequent change of data with note in the report history

Demands

- Concise presentation of demands

- Adding and editing of demands

- Automatic consideration of changed demands e.g. in the installations overview

Test report

- Planning of necessary tests and automatic generation of appropriate test orders

- Choice of single component to be tested from a bill of materials (for complex materials)

- Overview of states for test orders

- Checking, cancellation and editing of test orders

Parts characterisation and ingredients

- Classification of part and IMDS numbers

- Alternatively for IMDS numbers: possibility to exactly itemise all material components with automatic transfer from the bills of materials (see also iQ-GL)

- Environment- and security-related classification of ingredients by means of a checklist and declaration of an additional description with a detailed text

Actions

- Creating immediate actions directly within a report (see also iQ-PROJEKTE)

- Concise listing of all associated actions stating action state, person responsible and due date

Gauges

- Setting up any number of gauges

- Transfer of gauges from test

- Access to gauge administration (iQ-PMV)

Attachments (documents)

- Simple adding and storing or assigning any kind of document to a requirement (see iQ-DOKU)

- Direct editing of assigned documents

- Distribution and printing of documents - also in PDF format

- Use of templates (e.g. from Word and Excel)

Customer/supplier decision

- Detailed overview of the decision

- Note of decision for every requirement

- Detailed description for customer explanation

- Release

- Action plan for supplier report

Interfaces to other modules

- iQ-EMP for automatic setup of tests and their execution

- iQ-CAD-Interface, if you want/need to execute tests directly within CAD drawings

- iQ-DOKU for all aspects of document management

- iQ-PMV for administration of test equipment used and tracking & tracing regarding test equipment quality

- iQ-PROJEKTE for setup and automatic tracing of actions