Lieferantenmanagement

Die Produkte werden immer leistungsfähiger und anspruchsvoller. Kaum ein Unternehmen ist heute noch Hersteller aller Komponenten des Produktes. Die enge Zusammenarbeit bezieht den Lieferanten in allen Phasen des Produktes vom Design bis zur Entsorgung mit ein. Die Lieferantenbewertung (iQ-LIEFBEW) hilft bei der Beurteilung eines Lieferanten hinsichtlich der Qualitätskennzahlen mit Qualität, Logistik, Preis und Service/Systeme sowie Auswertungen.

Workflow

Die Module mit Lieferantenbezug liefern verdichtete Daten zur Lieferqualität an das Modul iQ-LIEFBEW. Die Daten werden dann über ein festgelegtes Verfahren bewertet und klassifiziert. Die Auswertung erfolgt auf verschiedenste Weise, soweit möglich, mit Standard-Übersichten und Statistiken. Diese decken die allgemeinen Anforderungen ab, dem Benutzer steht darüber hinaus mit iQ-INFO ein System zur Verfügung, mit dem er seine eigenen Fragestellungen selbst in Übersichten, Grafiken oder auch Formularen beantworten kann.

Wichtige Funktionen im Überblick

Unterschiedliche Sichtweisen

Lieferhistorie zu einem Lieferanten

- Gelieferte Artikel eines Lieferanten; einzeln und in Zusammenfassung eines Zeitraumes

- Liefertreue über Artikel eines Lieferanten

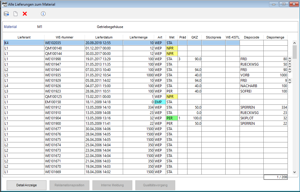

- Alle Lieferungen mit Ergebniszusammenfassung

Lieferhistorie zu einem Artikel

- Alle Lieferanten eines Artikels mit Qualitätsbewertung

- Monatliche Bewertung

- Hitliste der Lieferanten

- Liefertreue der Lieferanten im Vergleich

Qualitätsbewertung aus Prüfungen

- Grund der Prüfung, z. B. Erstlieferung, neuer Änderungsindex usw.

- merkmalsgenaue Zusammenfassung der Messergebnisse

- Umfang der Prüfung

- Referenz zum Prüfauftrag

- Verwendungsentscheid für die Maßhaltigkeit, Werkstoff und Funktion; Gesamt-Verwendungsentscheid

Wareneingangsprüfung, ereignisgesteuerte WEP, Nachprüfung

- Prüfauftrag, Prüfplan

- merkmalsgenaue Bewertungen, Zusammenfassung der Mess-ergebnisse

- Ereignisse des Prüfers

Darstellung der Qualitätskennzahlen

- Die Qualitätsdaten stammen aus den Verwendungsentscheidungen der Prüfungen, Lieferantenreklamationen (8D-Reports), ppm-Bewertungen und Lieferantenaudits der iQ-BASIS Module sowie aus händisch hinzugefügten Beurteilungen. Eigene Bewertungs-kataloge können erstellt werden. Im Standard stehen zur Verfügung:

- Termintreue

- Mengentreue

- Anlieferqualität

Qualität

- Erstmuster

- Serienteile

- Beanstandungen

- Kundenreklamationen

Service

- Kulanz

- Termin 8D-Report

- Reparaturen usw.

Preis

- Preisvergleich

- Preiskonstanz

Übersichten aller Prüfaufträge zum Teile-/Lieferanten-bezug, vollständige Lieferhistorie

- Erstmuster

- Wareneingänge

- Skiplots-, Annahmen ohne Prüfung

- Nachprüfung

- Ereignisgesteuerte Prüfungen (Fehleranalysen aus Qualitätsmeldungen)

- Auswertungen aller/einzelner Teile eines Lieferanten

- Auswertungen aller/eines Lieferanten zu einem Teil

- Zusammengefasste Bewertung eines Lieferanten (Gewichtung und Bewertung, teilweise manuelle Erfassung) hinsichtlich:

Darstellung Q-Kennzahlen (VDA, Bosch) und ppm-Bewertung (Liste, Grafik)

- Monatsstatistiken QKZ, ppm

- Sollvorgaben aus ppm-Verträgen

- Referenz zum Prüfauftrag

- mehrere unterschiedliche Materialdispositionen je Verwendungsentscheid

- Angabe Menge, Disposition (frei, Rücklieferung, usw.) und Beanstandung (iO, keine Maßhaltigkeit usw.)

- Bewertungen des Disponenten in Form von Standard-Texten

Diverse statistische Auswertungen

Schnittstellen zu anderen Modulen