Initial Sampling Inspection

The initial sampling inspection takes place prior to the serial production and goes along with it, e. g., when part specifications, processes, procedures etc. are changed at the supplier. The iQ-EMP component can be used for the classical process. Additionally, it is a key part of the iQ-BASIS "Purchasing" package.

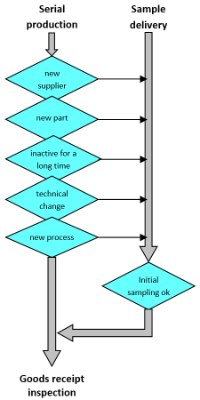

Workflow

As any other inspection oriented module, iQ-EMP is based on an inspection plan that has been previously created in iQ-PLAN. For an especially efficient creation, AHP offers the highly economic solution of automatically generating the inspection plan from a 2D CAD drawing (see also iQ-CAD-Interface).

As any other inspection oriented module, iQ-EMP is based on an inspection plan that has been previously created in iQ-PLAN. For an especially efficient creation, AHP offers the highly economic solution of automatically generating the inspection plan from a 2D CAD drawing (see also iQ-CAD-Interface).

For performing the actual inspection, it is required to previously generate an inspection order. This step can be done manually or automatically triggered from the ERP system.

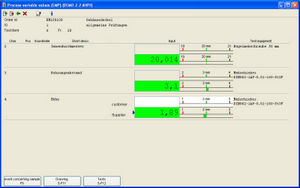

The inspector has access to different views allowing an optimized usage of the inspection environment for the upcoming inspection task. Interfaces to measuring devices and machines ensure a highly economical process. The usage decision that can also be made per characteristic is the last step before printing the initial sampling report (ISR) that can be tailored based on customer templates.

The results of the initial sampling inspection are evaluated and illustrated in the context of the supplier assessment module iQ-LIEFBEW together with results from the goods receipt inspections, repeated inspections and supplier complaints.

iQ-EMP meets the VDA requirements, especially with respect to the simultaneous sampling of purchasers and suppliers. It is even possible to involve the suppliers in the measuring process of the initial sampling inspections by providing them with the very simple iQ-EMP/AUTARK module that can be used to download measuring tasks from the CAQ PORTAL.

Important Features at a Glance

Order generation

An initial sampling inspection order can be generated manually or using an interface to the ERP system in the background. In any case, the following data is required:

- Reason for and procedure of the initial sampling

- Supplier, specification as supplier or customer including the plant address

- Material

- Reference to the goods receipt procedure of the sample delivery or to sampling during serial production

- Order number, delivery receipt etc.

- Number of the samples to be inspected, delivered quantity, and charge

- Priority and target inspection date

- Comment

Inspection

The default features for all the inspection oriented modules are described in the iQ-PAUF product sheet.

- Inspection mode as customer or/and supplier

- In customer mode it is also possible to record the sampling data of the supplier on a per characteristic level

- Recording of variable or attributive quality data in different forms of representation on part or characteristic level depending on the requirements. Additionally, a tabular form is supported.

- Further data of the test item such as serial number, nest, charge etc.

- Recording of special observations as events

- Completion of the inspection order by unplanned characteristics during the inspection. This is an important prerequisite for the initial sampling inspection that is not based on an extensive inspection planning.

Repeated initial sampling

- The inspection is only repeated for bad parts.

- The inspection is only repeated for characteristics that have been changed by design.

Additional data for the initial sampling inspection report

Any required fields for printing the VDA form such as

- Reason for the initial sampling inspection

- Summary of attachments and delivered documents

- Comments

Usage decision

- Option of a usage decision on characteristic level

- Separation of the decision into a development and a quality decision as well as an overall usage decision

- Recording of the usage decision with characteristic level inspection details into the history of the parts to supplier relation

- Reporting of the usage decision including report to the ERP system

- Printing of the initial sampling inspection report as a standard form

- Printing including a common distribution list for persons, departments and business partners

iQ-EMP as integrated module in the iQ-BASIS package "Purchasing"

- Consideration of the VDA reasons for the repeated initial sampling inspection when controlling the automatical initial sampling inspection order generation

- Forcing a repeated initial sampling inspection before a goods receipt event in case of rule violations or negative reports from an earlier initial sampling inspection

- Stopping of any goods receipt inspections or releases until the final initial sampling inspection usage decision

- Clear overview of any initial sampling inspections for a part of a supplier in history

- A number of control features for the iQ-BASIS package "Purchasing" when it is introduced. For example, it ensures that all the parts for the first months do not need to undergo an initial sampling inspection, again.

Evaluations

- Value pattern

- Order views according to different criteria

Report documents

- Cover sheet (VDA, custom)

- Depending on the inspection scope a measurements report, a raw material report, and a functional report

- Drawing with a colored marking of the stamps indicating if it is in order (green) or out of order (red)

Interfaces to Other Modules

- iQ-PLAN for planning defaults

- iQ-CAD-Interface for automatically building an inspection plan from a CAD drawing

- iT-IMAGE for storing images assigned to a characteristic of a sample part

- iT-IMPORTFILTER for reading measurements from a measuring machine

- iQ-EMP/AUTARK to enable the supplier to perform a measuring task

- CAQ-PORTAL for B2B communication with the supplier, for example, to provide the supplier with a measuring task

- iQ-DOKU for further document management features

- iQ-LIEFBEW in the context of the iQ-BASIS package "Purchasing" for calculating performance indicators for suppliers