Event controlled Receiving inspection

The component iQ-EWEP has been developed as a complement and alternative to the classical receiving inspection that is inefficient, ineffective and only partially practical for regular dealings between supplier and customer. Weak points of classical services become outdated with iQ-EWEP:

- The commonly practiced creation of a test flow chart per item is much too expensive

- The application of statistical means for random sample ascertainment leads to non-justifiably high testing expenditures

- The lowest problems are recognized in the goods received and so forth

Die ereignisgesteuerte Wareneingangsprüfung wird am wirksamsten in Verbindung mit dem Qualitätsmeldesystem iQ-QMS und der Komponente für Qualitätsprojekte eingesetzt (vergl. TQM für Zukaufteile).

The event controlled receiving inspection is used most effective in connection with the high-quality alarm system iQ-QMS and the component for high-quality projects (see TQM for to purchase part).iQ-EWEP is used for qualified suppliers, high volumes and parts from mastered processes, for parts with higher error rates, new part and new suppliers, a more extensive inspection must perhaps sometimes be accepted with iQ-WEP temporarily.

Inspection planning

- Detailed test flow chart if an individual part is to be tested not often but thoroughly

- Global test flow chart for any number of parts; it only includes some universal features (possible only inspection according to drawing or general inspection and so forth)

- Global inspection planning is complemented by knowledge base of the tester (see iQ-WEP)

- whole by adding unforeseen features during the inspection

- through precise error description

- Test flow chart kind global/detail can be chosen in a purposeful manner depending on the current situation

- Sample size can be assigned to one exact feature or to all features (inspection: test two parts)

- all control options for the inspection described in iQ-WEP are also valid in iQ-EWEP

Ship to stock contracts

- n deliveries become inspected at the beginning of a defined time period (e.g. once in the year)

- by activation of STS the last inspection can be deter-mined from the history

The periodic inspection

The preconditions are always meant for one parts no. of one supplier.

When using event controlled inspection it is assumed that a great number of deliveries is accepted untested. For this reason, there is a control that refers to the deliveries:

- Precondition of the number in result of deliveries or lots to be tested.

- if lots and deliveries are indicated simultaneously, the more crucial precondition is valid

- Explanation of the current situation (five deliveries in sequence to be tested, three already tested)

- Selection of the test flow chart to be employed (de-tail/global)

- Information of the sample size (number of parts to be tested e.g. n=2)

The following inspection preconditions for further events are built up similarly

Charge change

- Recording delivery batch with the goods received or separate by it

- Determination of the charge features, so that the charges specific features are only tested

new drawing change

- Recording of the update index in the goods received (e.g. VDA receipt)

- or update index according to change notice new to precondition

- Determination of the features to be tested which are concerned by change

Temporary inspection

- Information number of inspections

- up to one time

- from a time off

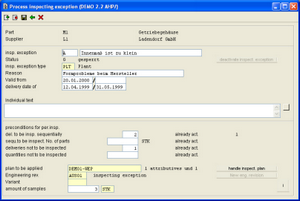

Building deviation/testing exception

- Recording building deviation;

- Status

- Model (intern precondition, supplier request)

- Reason

- Validity period

- For building deviation plants test flow chart change

- Over retention period control testing plane change states

- Determination of the features to be tested which are concerned by the building deviation

Event control

Various information can force an inspection for the next delivery of a part of a supplier.

- Supplier modified the process; for this, an primary model inspection before the normal inspection can be forced

- Designer introduces new update index

- High-quality administration arrested deficient quality by a supplier audit with the supplier

- Manufacturing, arrangement has erroneous ones to purchase divide locked

- Service has high returns on account of to purchase part

- Complained customer parts on account of mistakes on to purchase divide and so forth.

In different modules can or must put on an event to a part of a supplier.

For the inspection while acting event control, there are the following preconditions

- Number of the deliveries be tested in result and/or

- Number of the lots to be tested in result

- test flow chart to be applied, e.g. detailed test flow chart

- Sample size

Control of inspection order

A result of conditions is tested with every delivery.

- is the periodic inspection switched?

- is an event available?

- is another primary model test job open?

- is another inspection order arranged periodically open?

Supplies concatenation

As long as a decision of an older existing goods received is yet to come, every new test job is put into a queue. If the predecessor use decision is functional, testing renun-ciation can be allowed.

Primary model inspection order and post-test jobs are fully integrated into this control.

The inspection

The inspection occurs in same form as that for an inspection order of the component iQ-WEP. The same applies to the use decision and the history entry.

Post-test jobThe post-test job is required, e.g. if in manufacturing problems at one to purchase part were recognized and then the stocks have to be inspected.

For the post-test job applies

- manual generation

- free inspection plane choice and information of the random sample volume (e.g. 100% inspection)

- Inspection and iQ-WEP

- Use decision as iQ-WEP, however no response to PRODUCT PLANNING AND CONTROL system

- Entry into history with marking revision

Interface iQ-EWEP - iQ-QMS

The QMS-System is a strong component of high-quality problems for the recording, analysis and elimination, there-fore also for the complaints with purchase part combined those are not found in the course of a receiving inspection but from own fabrication or which are found only during the analysis of a customers complaint.

In iQ-QMS , the defect can be analysed

and described precisely. An event can be arranged to the high-quality announcement.

The error analysis of the high-quality announcement is announced for the tester at the time of the inspection

of the next goods received urgently to be tested.

The combination of iQ-EWEP and iQ-QMS makes it possible to handle the dialogue with the supplier not only by the classical complaint approach but by using the much more cooperative 8D report.